-

पाउच पैकिंग मशीन

-

दाना पैकिंग मशीन

-

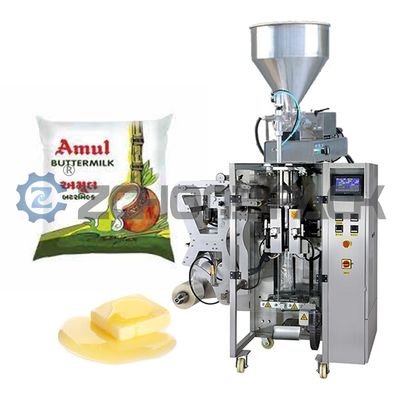

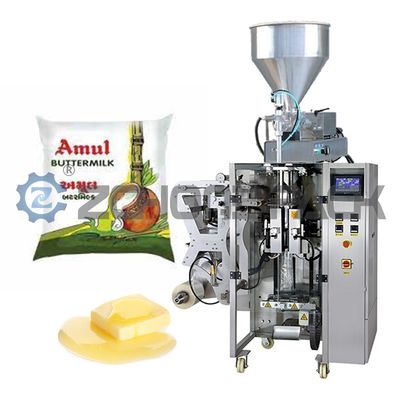

तरल पैकिंग मशीन

-

पाउडर पैकिंग मशीन

-

मिनी डोयपैक पैकेजिंग मशीन

-

चाय बैग पैकिंग मशीन

-

कॉफी पैकिंग मशीन

-

ऊर्ध्वाधर पैकिंग मशीन

-

फ्लो पैकिंग मशीन

-

पाउच पैकेजिंग मशीन खड़े हो जाओ

-

रोटरी वैक्यूम पैकेजिंग मशीन

-

भरने की मशीन

-

क्षैतिज डोयपैक पैकिंग मशीन

-

प्रेमाडे बैग

-

पैकिंग मशीन सहायक उपकरण

-

भरने और कैपिंग मशीन

ऊर्ध्वाधर फिल्म रोल बैग बनाने खाद्य खिलौना हार्डवेयर पैकेजिंग मशीन

| प्रकार | बहु-कार्य पैकेजिंग मशीन | प्रोडक्ट का नाम | मिनी डॉयपैक पैकिंग मशीन |

|---|---|---|---|

| गारंटी | 1 वर्ष | वारंटी सेवा के बाद1 | वीडियो तकनीकी सहायता |

| वारंटी सेवा के बाद2 | ऑनलाइन समर्थन | वारंटी सेवा के बाद3 | स्पेयर पार्ट्स |

| प्रमुखता देना | ऊर्ध्वाधर फिल्म रोल पैकेजिंग मशीन,खाद्य पैकेजिंग बैग बनाने की मशीन,हार्डवेयर वर्टिकल पैकिंग मशीन |

||

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

ऊर्ध्वाधर एफिल्म आरोल बीैग एमैकिंग एफूड टीॉय एचार्डवेयर पीैकेजिंग एमशीन

1. एक ऊर्ध्वाधर पैकेजिंग मशीन क्या है?

एक ऊर्ध्वाधर पैकेजिंग मशीन, जिसे "फॉर्म, फिल, और सील" पैकेजिंग मशीन के रूप में भी जाना जाता है, एक अत्यधिक स्वचालित पैकेजिंग मशीन है। इसका मुख्य परिचालन सिद्धांत पहले रोल फिल्म (पैकेजिंग फिल्म का एक रोल) का उपयोग करके साइट पर बैग बनाना है, फिर बैग को उत्पाद से भरना है, और अंत में उन्हें सील और काटना है।

2. मुख्य विशेषताएं

उच्च दक्षता: स्वचालित और निरंतर संचालन प्रति मिनट दर्जनों से सैकड़ों बैग की पैकेजिंग गति की अनुमति देता है।

सामग्री की बचत: रोल फिल्म का उपयोग सामग्री की लागत को कम करता है और पहले से बने बैग की तुलना में कम भंडारण स्थान की आवश्यकता होती है।

उच्च लचीलापन: विभिन्न मीटरिंग और फिलिंग डिवाइस और फीडर को बदलकर, यह विभिन्न प्रकार की सामग्रियों को पैक कर सकता है, जिसमें कण, पाउडर, तरल पदार्थ, पेस्ट और थोक उत्पाद शामिल हैं।

सौंदर्यपूर्ण पैकेजिंग: यह विभिन्न प्रकार के बैग प्रकार बना सकता है, जिसमें बैक-सील, तीन-तरफा सील, चार-तरफा सील और गसेटेड बैग शामिल हैं, और इसमें छिद्रण और आसान-टीयर नॉच जैसी अतिरिक्त विशेषताएं शामिल हो सकती हैं।

छोटा पदचिह्न: इसका ऊर्ध्वाधर डिज़ाइन एक कॉम्पैक्ट संरचना की अनुमति देता है, जो कार्यशाला में जगह बचाता है।

3.मुख्य कार्य सिद्धांत (तीन-चरणीय प्रक्रिया)

एक ऊर्ध्वाधर पैकेजिंग मशीन के वर्कफ़्लो को तीन मुख्य चरणों में स्पष्ट रूप से विभाजित किया जा सकता है:

I. बैग बनाना

फिल्म रोल को मशीन के पीछे सामग्री रैक पर लगाया जाता है।

फिल्म को बाहर खींचा जाता है, एक तनाव डिवाइस और गाइड रोलर्स से गुजरती है, और एक प्रमुख घटक—पूर्व में प्रवेश करती है।

पूर्व सपाट फिल्म को एक ट्यूब में रोल करता है। यह पूरी मशीन का "दिल" है। विभिन्न पूर्व अंतिम बैग आकार (जैसे बैक-सील बैग या चार-तरफा सील बैग) निर्धारित करते हैं।

II. भरना

फिल्म की बनी हुई ट्यूब नीचे की ओर जाती है और अनुदैर्ध्य सीलिंग डिवाइस से गुजरती है, जहां फिल्म की अनुदैर्ध्य सीम को गर्मी से सील किया जाता है ताकि ट्यूब को पूरा किया जा सके।

उत्पाद को मशीन के शीर्ष पर मीटरिंग और फिलिंग सिस्टम के माध्यम से बैग ट्यूब में गिरा दिया जाता है। मीटरिंग सिस्टम को सामग्री की विशेषताओं के आधार पर चुना जाता है और इसमें मापने वाला कप, पेंच, वजन या तरल पंप शामिल हो सकते हैं।

III. सीलिंग और कटिंग

भरने के बाद, अनुप्रस्थ सीलिंग डिवाइस (गर्मी-सीलिंग सिर की एक जोड़ी) चिमटी की एक जोड़ी की तरह कार्य करता है, बैग ट्यूब को क्लैंप करता है और इसे एक साथ ऊपर और नीचे गर्मी से सील करता है।

शीर्ष अनुप्रस्थ सील वर्तमान बैग की शीर्ष सील बनाता है, जबकि निचला अनुप्रस्थ सील अगले बैग की निचली सील बनाता है।

इसके बाद, अनुप्रस्थ सील के बीच में आंतरिक या बाहरी कटर शीर्ष और निचले बैग को अलग करता है, जिससे तैयार उत्पाद बैग बाहर गिर सकते हैं।

यह प्रक्रिया लगातार दोहराती है, जिससे निरंतर स्वचालित पैकेजिंग प्राप्त होती है।

4. मुख्य अनुप्रयोग

ऊर्ध्वाधर पैकेजिंग मशीनों का व्यापक रूप से उपयोग किया जाता है, जो ठोस और तरल पैकेजिंग दोनों के लिए लगभग सभी तेजी से चलने वाले उपभोक्ता वस्तुओं (एफएमसीजी) को कवर करता है:

खाद्य उद्योग: स्नैक्स, चिप्स, नट्स, कैंडी, नूडल्स, पालतू भोजन, मसाले, चाय, कॉफी, जमे हुए खाद्य पदार्थ, आदि।

दैनिक रासायनिक उद्योग: कपड़े धोने का डिटर्जेंट, शैम्पू, शॉवर जेल के नमूने, त्वचा देखभाल उत्पाद, गीले पोंछे, आदि।

फार्मास्युटिकल उद्योग: गोलियाँ, कैप्सूल, चीनी हर्बल दवा स्लाइस, और चिकित्सा ड्रेसिंग।

हार्डवेयर और इलेक्ट्रॉनिक्स: पेंच, नट और छोटे हिस्से।

कृषि रसायन: बीज, उर्वरक और कम खुराक वाले रासायनिक उत्पाद।

मशीन विनिर्देश:

| मॉडल | ZC--VP32 | ZC-VP42 | ZC-VP52 | ZC-VP62 |

| पैकिंग गति | 10-50 बैग/मिनट | 10-50 बैग/मिनट | 10-50 बैग/मिनट | 5~50 बैग/मिनट |

| बैग का आकार | (एल) 50- 190 मिमी (डब्ल्यू) 50-150 मिमी | (एल) 80-320 मिमी (डब्ल्यू) 70- 200 मिमी | (एल) 80-320 मिमी (डब्ल्यू) 70- 200 मिमी | (एल)120-400 मिमी (डब्ल्यू)110- 300मिमी |

| बैग बनाना फॉर्म | तकिया प्रकार बैक सील बैग (पैकेजिंग सामग्री के लिए रोल फिल्म, मशीन द्वारा स्वचालित बैग बनाना ऊपरी सीलिंग, निचला सीलिंग और बैक सीलिंग है।) | तकिया बैग (वैकल्पिक: स्टैंड-अप बैग, प्रोंग बैग, पंच बैग)) | ||

| अधिकतम पैकेजिंग फिल्म की चौड़ाई | 320मिमी | 420मिमी | 420मिमी | अधिकतम 2500ml |

| माप रेंज | 500ml | 1000ml | 1000ml | 620मिमी |

| झिल्ली मोटाई | 0.04- 0.12मिमी | 0.04-0.10मिमी | 0.04-0.10मिमी | 0.04-0.14मिमी |

| वायु का उपभोग का पूरा सेट | 0.8Mpa 0.5m3/मिनट | 0.8Mpa 0.3m³/分 | 0.8Mpa 0.3m³/分 | 0.8Mpa 0.5m3/मिनट |

| कुल पावर/वोल्टेज | 2.5KW/220V 50Hz | 2.7KW/220V 50Hz | 2.7KW/220V 50Hz | 4.2KW/220V 50Hz |

| आयाम | (एल)1350* (डब्ल्यू)820* (एच)1150मिमी | L1480*W960*H1400mm | L1480*W960*H1400mm | L1964*W1240*H1960mm |

| स्विचबोर्ड वजन | 380kg | 450kg | 450kg | 450kg |

(हम आपकी आवश्यकताओं के अनुसार आपको विशेष अनुकूलित सेवाएं प्रदान कर सकते हैं!)

![]()

![]()

![]()

![]()

![]()