-

पाउच पैकिंग मशीन

-

दाना पैकिंग मशीन

-

तरल पैकिंग मशीन

-

पाउडर पैकिंग मशीन

-

मिनी डोयपैक पैकेजिंग मशीन

-

चाय बैग पैकिंग मशीन

-

कॉफी पैकिंग मशीन

-

ऊर्ध्वाधर पैकिंग मशीन

-

फ्लो पैकिंग मशीन

-

पाउच पैकेजिंग मशीन खड़े हो जाओ

-

रोटरी वैक्यूम पैकेजिंग मशीन

-

भरने की मशीन

-

क्षैतिज डोयपैक पैकिंग मशीन

-

प्रेमाडे बैग

-

पैकिंग मशीन सहायक उपकरण

-

भरने और कैपिंग मशीन

High-Accuracy Automatic Freeze-Dried Fruit Machine Labeling, Sealing, Filling Functions, Vacuum-Sealed Plastic Bags/Pouches

निःशुल्क नमूने और कूपन के लिए मुझसे संपर्क करें।

WhatsApp:0086 18588475571

वीचैट: 0086 18588475571

स्काइप: sales10@aixton.com

यदि आपको कोई चिंता है, तो हम 24 घंटे ऑनलाइन सहायता प्रदान करते हैं।

x| प्रकार | स्वत: पैकेजिंग मशीन | प्रोडक्ट का नाम | खाद्य ग्रेन्युल बहु-स्टेशन पैकेजिंग मशीन |

|---|---|---|---|

| आयाम(एल*डब्ल्यू*एच) | L1900*W1400*H1450 | वजन (किलो) | 1300 |

| वोल्टेज | 110V 220V 380V 50Hz/60Hz | उत्पादन क्षमता | 20BAG/MIN, 50BAG/MIN, 30BAG/MIN |

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

High-Accuracy Automatic Freeze-Dried Fruit Machine Labeling, Sealing, Filling Functions, Vacuum-Sealed Plastic Bags/Pouches

Key Components and Functions of a Freeze-Dried Fruit Packaging Machine

A professional freeze-dried fruit packaging machine typically integrates the following modules to form an automated or semi-automated production line:

1. Feeding and Metering Filling System

Challenge: Freeze-dried fruits are large, lightweight, and fragile.

Solutions:

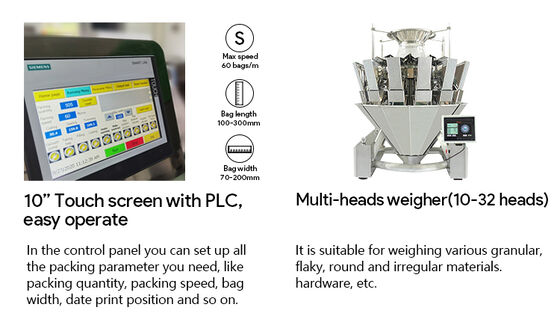

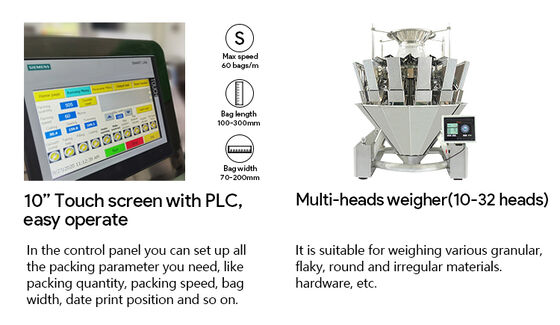

1) Weighing Filler (Multi-Head Scale): The most accurate and commonly used method. It achieves high-speed, high-precision weighing (accuracy up to ±0.1-0.5 grams) through the combination of multiple weighing hoppers, and is highly adaptable to product shapes.

2) Volumetric Filler: Suitable for products with uniform particle size. Weight is controlled by measuring volume; it is faster, but accuracy is affected by changes in product density.

3) Vibrating Feeder/Conveyor Belt: Gently conveys the product to the filling port, preventing breakage.

2. Vacuum-Filled Nitrogen System (Core)

Workflow:

a. Bag/Can Opening: Position the empty packaging container.

b. Filling: Add precisely measured amounts of freeze-dried fruit.

c. Vacuuming: Forcefully extract the air (containing oxygen and moisture) from the packaging container.

d. Sealing: Perform heat sealing (bags) or screw cap/compression cap (cans) in a nitrogen environment.

3. Sealing System

1) For bagged products: Use heat sealing to ensure a firm, smooth, and leak-free seal. A cooling device may be required to quickly set the seal.

2) For canned products: Use an automatic capping, screw capping, or compression capping device to ensure a tight seal.

4. Control System and Monitoring

1) PLC Control: Precisely control parameters such as time, vacuum level, nitrogen filling volume, and temperature at each step.

2) Residual Oxygen Detector (Optional but Important): Online or sampling detection of oxygen content within the finished product packaging is a direct indicator of packaging effectiveness and shelf-life assurance. High-quality freeze-dried packaging typically requires residual oxygen levels below 2%-3%, or even lower.

5. Auxiliary and Downstream Equipment

1) Vibration Leveler (Canning): Gently vibrates the can after filling to ensure a tighter product arrangement, reducing top space, saving nitrogen, and improving packaging stability.

2) Labeling Machine/Installation Machine: Prints production date, batch number, and other information.

3) Cartoning/Packaging Machine: Completes secondary packaging.

High-Accuracy Automatic Freeze-Dried Fruit Machine Labeling Sealing Filling Functions Vacuum-Sealed Plastic Bags/Pouches

Machine Specification:

| Item | ZC-X8200 | ZC-X8250 | ZC-X8300 |

| Packing speed | MAX 60 bags/min,depending on the quality of the packaging film,packaging materials packaging weight etc. | ||

| Bag size | (L)100-300mm (W)70- 200mm | (L)100-350mm (W)130- 250mm | (L)150-450mm (W)200-300mm |

| Bag type | Pre-mede bags,Stand-up bag,four-side sealed bag,three-side sealed bag,special-shaped bag | ||

| Weighing range | 10g-1kg | 10g-2kg | 10g-3kg |

|

Measurement accuracy |

*≤±0.5~1%, depending on the measuring equipment & materials. | ||

| Maximum bag width | 200mm | 250mm |

300mm |

| Gas consumption | 0.8Mpa 0.3m3/min (Supply by user) | ||

| Total Powder/Voltage | 2.5KW 380V 50/60Hz | 2.5KW 380V 50/60Hz | 3.7KW 380V 50/60Hz |

| Air compressor | Not less than 1CBM | ||

| Dimension | L1900*W1400*H1450 | L1900*W1400*H1450 | L2000*W1500*H1550 |

| Machine Weight | 1300kg | 1400kg | 1500kg |

| Work flow | Giving bag→Coding→Opening bag(or Open zipper bag)→Filling→ Auxiliary→Exhaust→Heat sealing→Forming and output products. | ||

| Applicable scope | Granular type: crystal monosodium glutamate, granular drug, capsule, seeds, chemicals, sugar, chicken essence, melon seeds, nut, pesticide, fertilizer, etc | ||

(We can provide you with exclusive customized services according to your needs!)

![]()

![]()

![]()

![]()