-

पाउच पैकिंग मशीन

-

दाना पैकिंग मशीन

-

तरल पैकिंग मशीन

-

पाउडर पैकिंग मशीन

-

मिनी डोयपैक पैकेजिंग मशीन

-

चाय बैग पैकिंग मशीन

-

कॉफी पैकिंग मशीन

-

ऊर्ध्वाधर पैकिंग मशीन

-

फ्लो पैकिंग मशीन

-

पाउच पैकेजिंग मशीन खड़े हो जाओ

-

रोटरी वैक्यूम पैकेजिंग मशीन

-

भरने की मशीन

-

क्षैतिज डोयपैक पैकिंग मशीन

-

प्रेमाडे बैग

-

पैकिंग मशीन सहायक उपकरण

-

भरने और कैपिंग मशीन

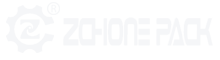

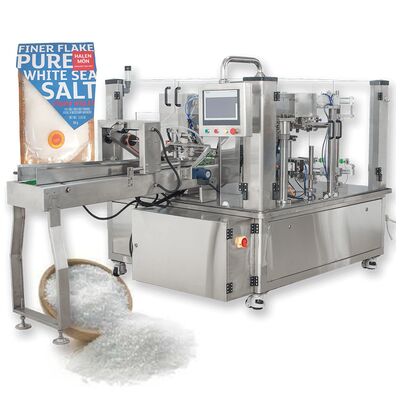

Eight-Station Fully Automatic Food Packaging Equipment for Edible Salt Packaging with Dust Removal and Cleaning System

निःशुल्क नमूने और कूपन के लिए मुझसे संपर्क करें।

WhatsApp:0086 18588475571

वीचैट: 0086 18588475571

स्काइप: sales10@aixton.com

यदि आपको कोई चिंता है, तो हम 24 घंटे ऑनलाइन सहायता प्रदान करते हैं।

x| प्रकार | स्वत: पैकेजिंग मशीन | प्रोडक्ट का नाम | खाद्य ग्रेन्युल बहु-स्टेशन पैकेजिंग मशीन |

|---|---|---|---|

| आयाम(एल*डब्ल्यू*एच) | L1900*W1400*H1450 | वजन (किग्रा) | 1300 |

| वोल्टेज | 110V 220V 380V 50Hz/60Hz | उत्पादन क्षमता | 20BAG/MIN, 50BAG/MIN, 30BAG/MIN |

| प्रमुखता देना | fully automatic food packaging machine,edible salt packing machine with dust removal,granule packing equipment with cleaning system |

||

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

Eight-Station Fully Automatic Food Packaging Equipment for Edible Salt Packaging with Dust Removal and Cleaning System

The eight-station bag-feeding edible salt packaging machine is a widely used automated packaging equipment in the food and condiment industries. It is particularly suitable for packaging powdery or small granular materials like edible salt, which have good flowability and stable density.

I. Core Features of the Equipment

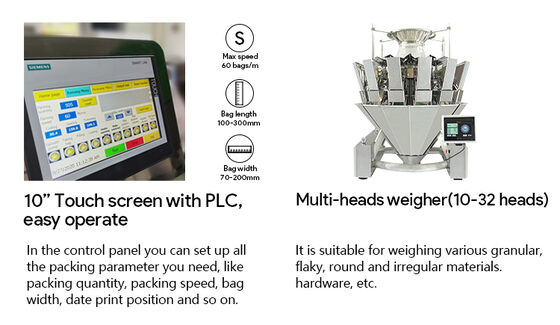

1. Eight-station turntable: This is the core structure of the machine. Eight workstations are evenly distributed on a horizontally rotating turntable, each performing different packaging processes simultaneously, achieving continuous cyclic operation and significantly higher efficiency than single-station or linear packaging machines.

2.Bag-feeding type: Unlike bag-making packaging machines, it uses pre-made finished packaging bags (usually back-seal or four-side-seal bags). These bags can be pre-printed with exquisite patterns and trademarks, resulting in better brand display.

3. Fully automated: From bag loading, bag opening, metering and filling, degassing (or vacuuming), sealing to finished product output, the entire process is automated. Manual labor is only required to add empty bags and replenish materials periodically.

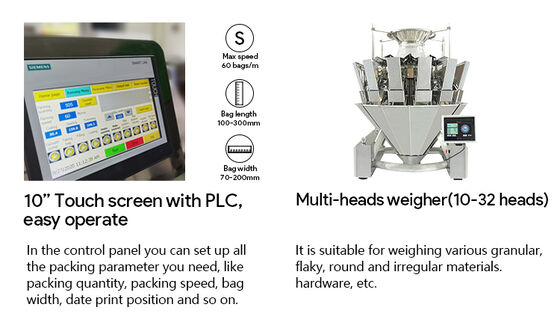

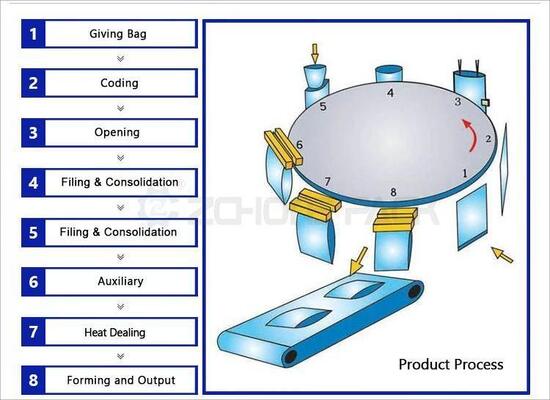

II.Standard Workflow (Eight stations completed sequentially)

Station 1: Bag Retrieval and Loading: A robotic arm or suction cup accurately retrieves a pre-made bag from the bag magazine and clamps it securely at the station.

Station 2: Bag Opening and Bag Opening Cleaning: The clamp pulls open the bag opening, and a blowing device may be used to clean any dust or foreign objects inside the bag (crucial for food hygiene).

Station 3: Metering and Filling: This is the key to edible salt packaging. A high-precision screw metering machine or measuring cup device accurately fills the bag with the set weight of edible salt. Accuracy is typically ±0.5~1 gram.

Station 4: Auxiliary Feeding/Vibration: An auxiliary device may be used to ensure the material inside the bag reaches the bottom, preparing for sealing.

Station 5: Shaping and Pre-sealing: The filled bags are tidied up, and the bag opening may undergo preliminary heat sealing or finishing to ensure a smooth seal later.

Station 6: Heat Sealing: The bag opening is finally heat-sealed. Depending on the requirements, sealing can be simple heat sealing, or vacuum sealing followed by sealing, or nitrogen filling followed by sealing (generally not necessary for edible salt, but may be considered for high-end salt or anti-caking requirements).

Station Seven: Cooling and Shaping: Allows the sealed area to cool and solidify, ensuring sealing strength.

Station Eight: Finished Product Output: Releases the packaged bags onto the conveyor belt or collection basket, completing the counting.

III. Special Advantages for Edible Salt Packaging

1. High-Precision Metering: Employs a stainless steel corrosion-resistant screw metering system, ensuring high accuracy and fully complying with national quantitative packaging regulations.

2. Corrosion-Resistant Design: Parts in contact with edible salt (such as the hopper, screw, and filling nozzle) are made of 304 or 316 stainless steel to prevent corrosion and contamination.

3. Dustproof and Cleanable: The equipment is designed for easy cleaning, reducing cross-contamination of dust and meeting food production requirements.

4. High Speed: The eight-station design is highly efficient, typically achieving speeds of 40-60 bags/minute (depending on bag size and weight), making it ideal for large-scale production.

5. Attractive Packaging: Using pre-made colored bags enhances product quality and market competitiveness.

6. Relatively Convenient Changeover: By changing the bag clamps, metering screws, and adjusting parameters, it can accommodate salt bags of different sizes and weights.

IV. Conclusion

The eight-station bag-feeding packaging machine is an ideal choice for medium to large-scale edible salt production enterprises, achieving a good balance between efficiency, precision, and packaging aesthetics. When purchasing, we strongly recommend providing you with sample bags and materials for on-site testing.

Machine Specification:

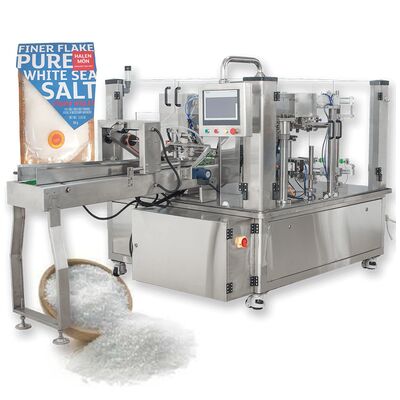

| Item | ZC-X8200 | ZC-X8250 | ZC-X8300 |

| Packing speed | MAX 60 bags/min,depending on the quality of the packaging film,packaging materials packaging weight etc. | ||

| Bag size | (L)100-300mm (W)70- 200mm | (L)100-350mm (W)130- 250mm | (L)150-450mm (W)200-300mm |

| Bag type | Pre-mede bags,Stand-up bag,four-side sealed bag,three-side sealed bag,special-shaped bag | ||

| Weighing range | 10g-1kg | 10g-2kg | 10g-3kg |

|

Measurement accuracy |

*≤±0.5~1%, depending on the measuring equipment & materials. | ||

| Maximum bag width | 200mm | 250mm |

300mm |

| Gas consumption | 0.8Mpa 0.3m3/min (Supply by user) | ||

| Total Powder/Voltage | 2.5KW 380V 50/60Hz | 2.5KW 380V 50/60Hz | 3.7KW 380V 50/60Hz |

| Air compressor | Not less than 1CBM | ||

| Dimension | L1900*W1400*H1450 | L1900*W1400*H1450 | L2000*W1500*H1550 |

| Machine Weight | 1300kg | 1400kg | 1500kg |

| Work flow | Giving bag→Coding→Opening bag(or Open zipper bag)→Filling→ Auxiliary→Exhaust→Heat sealing→Forming and output products. | ||

| Applicable scope | Granular type: crystal monosodium glutamate, granular drug, capsule, seeds, chemicals, sugar, chicken essence, melon seeds, nut, pesticide, fertilizer, etc | ||

(We can provide you with exclusive customized services according to your needs!)

![]()

![]()

![]()

![]()